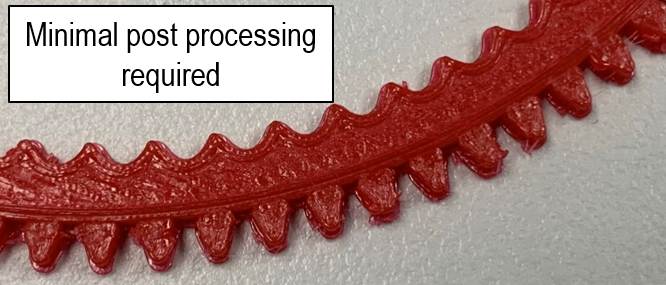

Printing parts using flexible polymers like TPU is always a challenge. Printing highly detailed parts is even more difficult. But don't be discouraged. With a little bit of testing and dialing in your slicer settings you can produce quality parts that are easy to clean up in post processing.

The Challenge

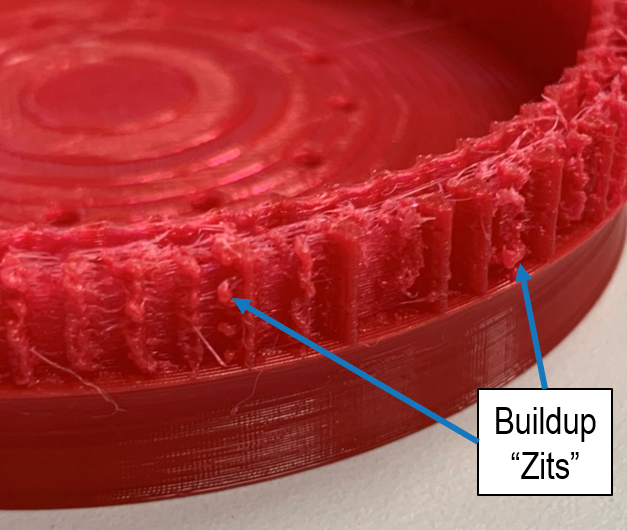

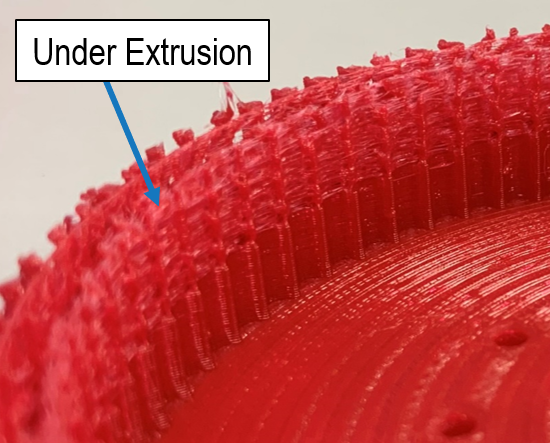

Printing parts with small features can cause the nozzle to move between many different extrusion paths. This excessive nozzle travel can cause stringing, whiskers, and surface buildup (blobs/zits) that are difficult to clean up during post processing. In the worst case, the excessive travel can cause under extrusion and a failed print.

What Causes Oozing

Let's start by discussing the three factors that cause oozing and then in the next section we will talk about slicer settings and how to balance them to improve print quality.

Residual Pressure

When printing, pressure inside of the nozzle forces molten material to extrude onto the build plate. The actual pressure in the nozzle is a function of the printer feed force (from the filament feeding mechanism), the geometry of the nozzle, and the physical properties of the material at temperature. This pressure is what creates the material extrusion feed rate from your nozzle (make sure not to confuse this with the printing speed rate that is related to the carriage movement).

When the nozzle travels from one location to another (changes extrusion paths), the pressure remains the same unless you take some action to reduce it. You can reduce the pressure in the nozzle by retracting or stopping the filament feed rate. If you aren't familiar with retraction, it is when the feed rate of the filament is reversed and the filament is pulled away a specified distance from the nozzle for a short period of time. Even when retracting filament, the pressure inside the nozzle can never be completely reduced to zero. Small amounts of material will continue to be extruded causing oozing.

Gravity

The force of gravity is constantly pulling down on the material. The physical properties of the material at a given temperature and the geometry of the nozzle will determine how much extrusion resistance the material has against gravity.

You can visualize this effect by comparing engine oil and water at room temperature. If you pour each of these fluids through a nozzle that is 1mm in diameter, how do you think they will behave? The engine oil will have a slower flow rate because it is more viscous than the water.

Time

The amount of oozing that occurs during travel movements is due to the rate that the material leaks from the nozzle (mm/s). Therefore, the amount of time it takes for the nozzle to travel from one location to another will also have an effect on the amount of oozing and the quality of your prints. Decreasing the time it takes for the nozzle to travel from one location to another while it is inactive (not extruding material) will reduce the amount of oozing that can occur.

Oozing & Under Extrusion - A Balance

There is a delicate balance between controlling oozing and avoiding under extrusion when working with flexible polymers. It can take some testing to get it correct for your machine and application. Let's talk about the effect of various slicer settings and how to balance them in order to produce a quality print. You should consider how all of these work together in order to get the best outcome.

Retraction

Enabling retraction when using flexible filaments is usually not recommended, especially with detailed prints. There are a couple of reasons for this.

The first reason is because the material can wear down at the feeder mechanism due to the excessive back and forth travel of the filament during retractions. It grinds down the filament. Once this happens, the feeder will have difficulty grabbing on to the filament wire and the pressure in the nozzle will reduce. The result is under extrusion and/or a warning that there is no more material in the nozzle.

Eliminating retraction failures for detailed TPU parts is even harder to control with Bowden style printers because the feeder mechanism is located far away from the nozzle. The high elasticity of flexible material can cause the filament to stretch rather than pull away from the nozzle. This can result in even more degradation of the filament at the feeder.

Another reason to turn off retraction is because the process takes time and material will still continue to ooze. The nozzle is typically stationary at the start and end points of travel movement (however I believe some slicers allow you to program retraction while moving the nozzle). This can deposit excess material at those points causing blobs.

When printing with flexible materials, some stringing and post processing should be expected. Minimizing it should be your goal. If you want to experiment with using retraction, my recommendation would be to reduce the occurrence of retractions as much as possible to avoid grinding the filament.

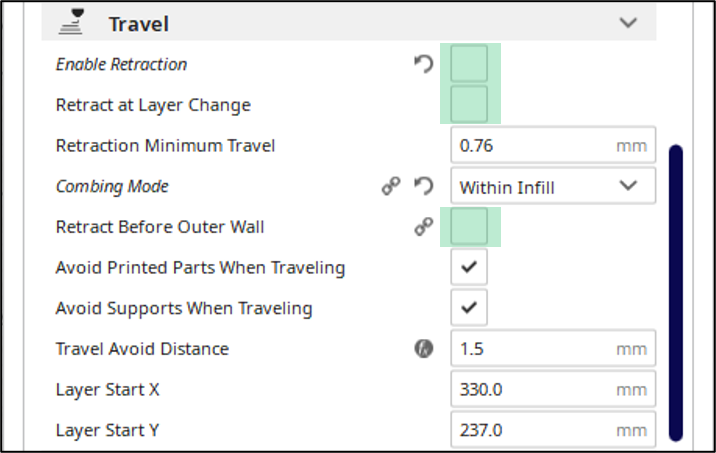

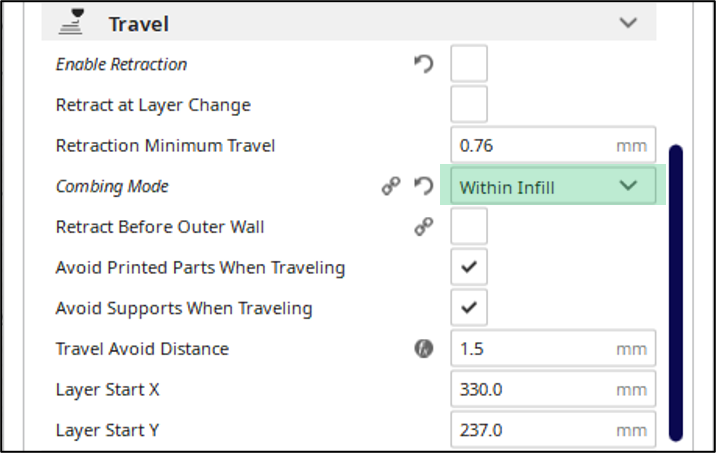

Below are some Cura settings that have worked for us. Again, these may be different for your machine and application. Depending on your level of experience, you can also add post process scripts that will adjust retraction settings for specific layers. For example, if you know your detailed features are on layers 15 - 20, then you can turn retraction off for only those layers.

Enable Retraction = Off

This setting will eliminate the excessive retraction. As an alternative solution, you may want to experiment with keeping this on, but increase the "Retraction Minimum Travel". If your problems are occurring because of excessive retraction between detailed features that are located close together (such as gear teeth), this could fix it. Try increasing the distance to a value bigger than the distance between those features.

Retract at Layer Change = Off

This setting retracts the filament when the machine is moving to the next layer. Turning it off avoids unnecessary retractions and inactive nozzles. Remember that the nozzle is stationary when a retraction is performed and oozing can cause excess material to be deposited at locations where a layer change is performed.

Retract Before Outer Wall = Off

This setting instructs the printer to retract when traveling to an outer wall. Again, turning this off may result in stringing, but will reduce the number of retraction occurrences if your print requires a lot of nozzle travel between features.

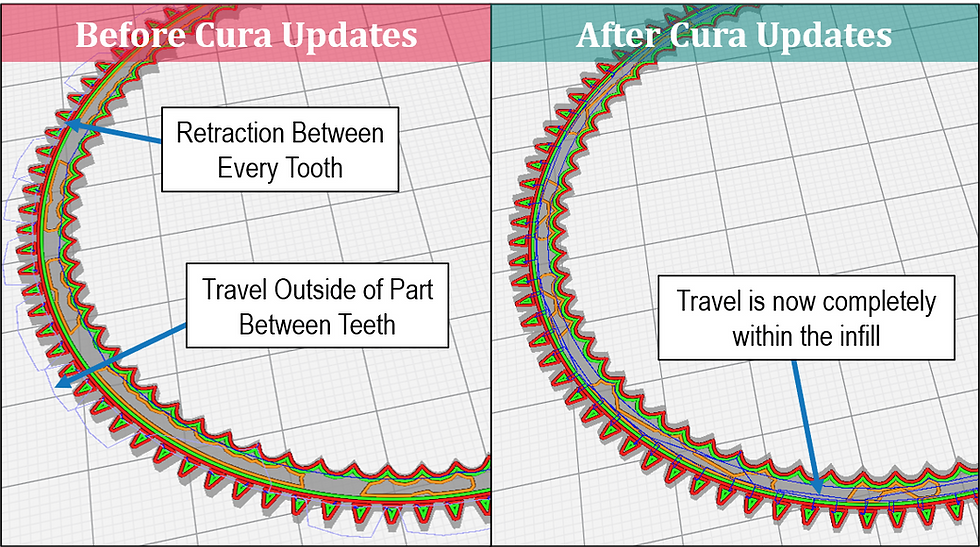

Combing

Combing tells the machine to avoid the walls of the print when travelling from one place to another. This helps avoid leaving scars on the surface of the print due to the hot nozzle passing over walls. It can also help to direct the travel of the nozzle so that oozing occurs in locations on the print that does not affect the outer surface.

Combing Mode = Within Infill

Setting the Combing Mode to "Within Infill" is the strictest mode and only allows combing through infill (if a layer has infill). It could increase the nozzle travel distance and total print time, but it keeps the oozing within the infill. If a print does not have infill, this may not help, but it can significantly reduce the stringing on the outside of your print in most layers that have infill.

Travel Speed

Turn this up as high as your printer can handle. It will reduce the time to move from one travel point to another, thus reducing the amount of oozing.

Coasting

I don't use this feature in Cura, but it may reduce blobs at the end of an extrusion path and oozing between travel movements. When this feature is enabled, you can adjust variables that will force the material to stop extruding slightly before finishing a wall contour. This will allow the nozzle to empty a little bit before performing travel movements, thus reducing pressure and oozing.

Print Speed & Nozzle Temperature

Adjusting the print speed and nozzle temperature can improve your final print quality. Both settings have an effect on the material flow rate.

A lower material flow rate reduces the pressure inside the nozzle which will result in less oozing. As an added benefit, it may also reduce filament grinding at the feeder because less force on the filament is required to maintain the lower flow rate.

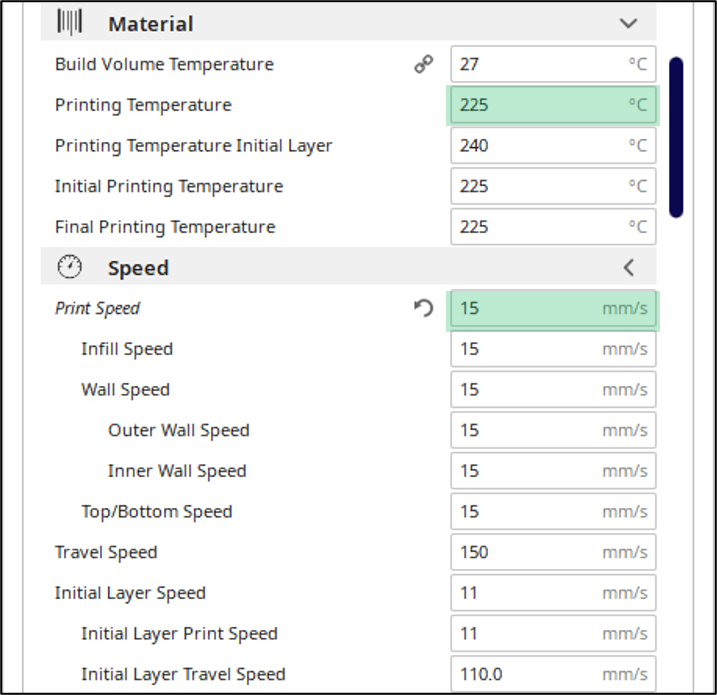

You will need to find the optimum speed/temperature point for your specific machine, application, and material. Nozzles and temperature sensors are different on each machine, so fine tuning is required. Below are settings that have worked for us when fabricating detailed parts with TPU95. In general, slowing down the print and reducing the nozzle temperature has helped us reduce stringing and surface defects.

Print Speed = 15 mm/s

Printing Temperature = 225 C

A note about nozzle temperature: When you adjust the nozzle temperature, you are not directly adjusting the material temperature that is exiting the nozzle. You are adjusting the temperature applied to the material. The resulting material temperature is a function of the nozzle temperature, the length of the nozzle cavity, and the flow rate of the material through the nozzle. Hence these settings may be different for different machines.

Balancing the Settings - Conclusion

Remember that you cannot take the settings we use and apply them directly to your application. However, they can be a good starting point. You should run samples and adjust them until you figure out the correct balance.

A final hint: Review the nozzle travel movement in your slicer for each layer. This will give you a good idea on where the nozzle exits the body of the part and where the retractions occur. In Cura, dark blue travel lines represent no retraction during movement and light blue lines represent retraction. Adjusting your settings to reduce retractions and nozzle travel that occurs outside the body will improve your printing success with flexible filaments like TPU.

Sign up for our newsletter to get email alerts when new articles are posted. You can find a link on the main page of our website. We will be posting loads of engaging content, so be sure to sign up ASAP!

At Nexus3, we partner with businesses to bring their innovations to life. If you have an engineering challenge that needs solving or if you need parts fabricated using AM technology, contact us. We will help you solve your toughest problems.

- Nexus3 is your innovation partner. Let us help you realize what is possible.

Comentarios